CNC Milling and Vertical Milling Servicesadmin2023-03-29T22:29:16-04:00

At D&E Machine Company in Lebanon, Ohio, we specialize in handling small-run production volumes of 200 units or less. We can also work with one-off parts and prototyping for the auto and robotics industries.

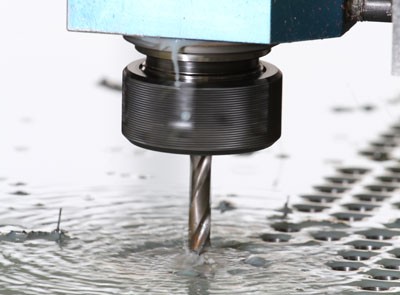

Our advanced CNC milling technology improves cycle time while processing high-quality parts at reduced costs. We partner with qualified suppliers, and this enables us to make parts to your specifications. This includes heat treating, plating, painting, and other processes.

Four-Axis Milling

At D&E Machine Co., we have a full, four-axis mill shop. We offer tight tolerances on product dimensions and can work with most metals and plastics, including cold and hot-rolled steel.

Our CNC milling equipment has 4th axis capabilities and a 50X98X22 inch work envelope. This meets the needs of most industries in the region, including steel mills, and second and third-tier automotive businesses that need vital parts. In addition, we provide a variety of industries with OEM replacement parts and reverse engineering of obsolete parts you can’t buy or repair.

We invite you to contact us today for more information about our CNC milling services!

Recent CNC Milling Projects

4th Axis Millingadmin2016-02-08T21:11:12-05:00 Precision Millingadmin2016-02-08T21:08:31-05:00 Milling with Protocol Controladmin2016-02-08T21:06:33-05:00 Large Plate Millingadmin2016-02-08T21:05:22-05:00 CNC Milling – Plasticadmin2016-02-08T21:04:18-05:00 Large Plate Millingadmin2016-02-08T21:02:46-05:00 CNC Milling of Plasticadmin2016-02-08T20:57:50-05:00

CNC Milling and Vertical Milling Services Specifications

| Industry Focus |

Auto/Truck/Transportation (2nd& 3rd tier supplier)

Design & Build

Equipment Manufacturers

Farm – replacement parts & reverse engineering of obsolete parts

Food – parts for food equipment

Government agencies

Industrial Maintenance |

Machine Tool

Medical Prototyping & Equipment Mfg.

Oil Field

Plastic Blow Molding

Packaging/Converting

Product Development

Steel Mills |

|

|

|

| Intended Application |

Machine components

Shafts

Pins

Thread rod |

Spindles

Bushings

Spacers |

|

|

| Vertical Milling Processes |

Drilling

Boring

Counterboring

Countersinking |

Pocketing

Profiling

Reaming

Tapping |

|

|

| Materials (Metals) |

Alloy Steels

Aluminum

Brass

Bronze Alloys

Carbon Steel |

Copper

Iron

Lead

Stainless Steel |

|

|

| Materials (Plastic Polymers) |

ABS (Acrylonitrile Butadiene Styrene)

Acetal

Acrylic

Fiberglass Reinforced Plastics

Nylon

Phenolic

Polyetheretherketone (PEEK) |

Polyethylene

Polypropylene

PTFE (PolyTetraFluoroEthylene)

PVC (Polyvinyl Chloride)

PVDF (Polyvinylidene Fluoride)

Teflon |

|

|

| Type of Milling Machines |

Vertical Machining Centers |

|

| Axes |

4 |

|

| Type of Collet/ Adapter |

| Spindle- have a standardized spindle end |

Chuck- used to attach chucks to milling machines having a standard spindle end |

|

|

| Vise |

|

|

| Equipment Capabilities |

Electric-drive motors

Coolant systems

Variable spindle speeds |

Power-operated table feeds

High speed machining |

|

|

| Tolerances |

Straightness : ± 0.001 in

Concentricity: ± 0.001 in |

Diameter (outer/inner): ± 0.001 in

Length): ± 0.001 in |

|

|

| Length |

Max

50 in

1270 mm |

|

| Width |

Max

98 in

2489.2 mm |

|

| Height |

Max

22 in

558.8 mm |

|

| Production Volume |

Min

1 Unit |

Max

100 Units |

|

Specialty Production Shop

Prototype |

Low Volume

Small Run |

|

|

| Lead Times Available |

Quoted on job by job basis |

|

| File Formats |

AutoCAD (DWG,DWZ)

BMP

Bit Mapped Graphics

DXF

Drawing Interchange Format, or Drawing Exchange Format

GIF

Graphics Interchange Format

IGES

Initial Graphics Exchange Specification, ANSI file format. |

JPG or JEPG

Joint Photographic Experts Group

MasterCam (MCX, MC8, MC9, SET)

PDF

Portable Document Format

SolidWorks (SLDPRT,SLDDRW,SLDDRT)

Tagged Image File Format |

|

|

| Outsourced Services |

Deep hole Drilling

Broaching

Plating

Passivating

Etch and Chromating

Heat Treating |

Centerless, ID & OD Grinding

Anodizing

Sandblast

Forming

Powder Coat Painting |

|