Precision CNC Turning Servicesadmin2023-03-29T22:43:54-04:00

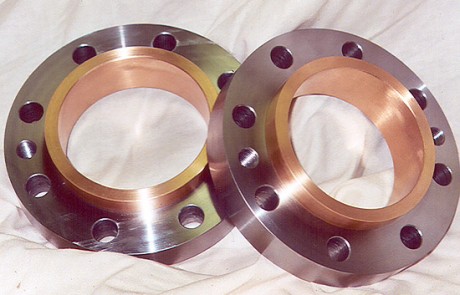

Specializing in one-off prototypes and small-run production volumes of 1000 units or less, our machine shop can manufacture a wide variety of components – offering precision tolerances as low as (+/-) 0.001 on all part dimensions. Our CNC turning machinery is equipped with both live tooling and live spindle capabilities and offers a four-inch through spindle capacity of up to 48 inches between centers. We also offer a 24-inch manual chucking capacity of up to 120 inches between centers.

Our advanced CNC turning equipment can work with a wide variety of materials, ranging from aluminum and stainless steel to fiberglass-reinforced plastics and PVC. We can also work with cold-rolled steel and hot-rolled steel. Our CNC turning services have successfully met the needs of diverse businesses, including the oil and plastic bottle-making industries. Our partnerships with qualified suppliers allow us to make your parts complete including heat treating, plating, painting, and more. We create higher-quality products at competitive prices. Contact D&E Machine Company, a machine shop in Ohio, to learn more about our CNC turning products and capabilities!

Our team has more than 40 years of experience. We can:

- Manufacture OEM replacement parts you can’t buy anymore.

- Prototype parts and components for the automotive and robotics industries.

- Reverse engineer a part you need for industrial equipment.

- Specialty machine parts and components.

- Perform CNC milling, vertical milling, and four-axis milling as well as machining and machining repair.

- Machining and machining repair.

Recent CNC Turning Projects

Small CNC Milling & Turningadmin2016-02-08T21:21:53-05:00 Knurled and Threaded End Capadmin2016-02-08T21:20:51-05:00 Shaft Collarsadmin2016-02-08T21:20:08-05:00 Rubber Gasket Moldadmin2016-02-08T21:19:16-05:00 Precision CNC Turningadmin2016-02-08T21:17:00-05:00 CNC Turning of Plasticadmin2016-02-08T21:15:59-05:00 CNC Turningadmin2016-02-08T21:14:52-05:00

Precision CNC Turning Services Specifications

| Industry Focus |

Auto/Truck/Transportation (2nd& 3rd tier supplier)

Design & Build

Equipment Manufacturers

Farm – replacement parts & reverse engineering of obsolete parts

Food – parts for food equipment

Government agencies

Industrial Maintenance |

Machine Tool

Medical Prototyping & Equipment Mfg.

Oil Field

Plastic Blow Molding

Packaging/Converting

Product Development

Steel Mills |

|

|

| Intended Applications |

Machine components

Shafts

Pins

Thread rod |

Spindles

Bushings

Spacers |

|

|

| Tolerances |

Straightness : ± 0.0005

Concentricity: ± 0.001

Diameter (outer/inner): ± 0.001 in

Length (over in): ± 0.001in |

|

| Part Diameter |

Max Though Spindle

4in |

Max Chucking

24in |

|

|

| Part Length |

Manual Max

120in |

CNC Max

48in |

|

|

| Machining Processes |

Parting/Cutting

Facing

Turning:

- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

Threading

|

Internal Forming

Knurling

Boring

Drilling

Counterboring

Countersinking

Pocketing

Profiling

Reaming

Tapping |

|

|

| Materials (Metals) |

Alloy Steels

Aluminum

Brass

Bronze Alloys

Carbon Steel |

Cobalt

Copper

Iron

Stainless Steel

Tin |

|

|

| Materials (Plastic Polymers) |

ABS (Acrylonitrile Butadiene Styrene)

Acetal

Acrylic

Fiberglass Reinforced Plastics

Nylon

Phenolic

Polyamide-Imide

Polycarbonate

Polyetheretherketone (PEEK)

Polyetherimide |

Polyethylene

Polyphenylene Sulfide

Polypropylene

Polystyrene

Polysulphone

PTFE (PolyTetraFluoroEthylene)

PVC (Polyvinyl Chloride)

PVDF (Polyvinylidene Fluoride)

Teflon |

|

|

| Materials (Other Materials) |

| Ceramic |

Composite Materials |

|

|

| Equipment |

|

|

| Fixturing |

Three-jaw chuck

Four-jaw chuck |

Pallets

In-House Fixturing & Tooling |

|

|

| Equipment Capabilities |

CNC Control Capabilities

Large Swing Lathe

Milling |

CAD Design Services

CAM Programming Services

Reverse Engineering |

|

|

| Machinery Axis |

3

Live Tooling |

|

| Secondary Services Offered |

Assembly

Drilling

Tapping

Bending

Threading

Counter Sinking |

Pressing

Milling

Reaming

Welding |

|

|

| Advantages of Turning |

Tight tolerances

Short lead times |

Materials compatible |

|

|

| Production Volume |

1min

1000max

Prototype

Low Volume |

Small Run

Large Run

Long Run |

|

|

| Lead Times Available |

Quoted on job by job basis

Emergency services available |

Rush Services Available |

|

|

| File Formats |

AutoCAD (DWG,DWZ)

BMP

Bit Mapped Graphics

DXF

Drawing Interchange Format, or Drawing Exchange Format

GIF

Graphics Interchange Format

IGES

Initial Graphics Exchange Specification, ANSI file format.

Inventor (IDW, IPT)

JPG or JEPG

Joint Photographic Experts Group |

MasterCam (MDX, MC8, MC9, SET)

PDES

Product Data Exchange using STEP, Standard for the Exchange of Product Model Data. A standard format for exchanging data between advanced CAD and CAM programs.

PDF

Portable Document Format

SolidEdge (DFT)

SolidWorks (SLDPRT, SLDDRW, SLDDRT) |

|

|

| Outsourced Services |

Deep Hole Drilling

Broaching

Plating

Passivating

Etch and Chromating

Heat Treating |

Centerless, ID & OD Grinding

Anodizing

Sandblast

Forming

Powder Coat Painting |

|