As manufacturing processes evolve, more businesses are turning to computer numerical control (CNC) machining for increased precision, reliability, and affordability. CNC machining has come a long way from its early roots in the 1960s, when it was first developed as a tool for mold making.

Now both CNC turning and CNC milling offers solutions that are integral to the success of modern mass production operations. D&E Machine Co. discusses how these two versions of CNC technology benefit the manufacturing industry.

What are CNC milling and CNC turning, and how do they work?

CNC machining refers to various subtractive machining methods. Subtractive machining involves removing pieces of the material to create a part. The fundamental difference between the two techniques lies in the movement of the cutting tool.

The process used for both techniques is similar. A design is programmed into the machine, and the tool moves through the material to create a finished product. The end result is a precise and efficient method for creating complex parts and components.

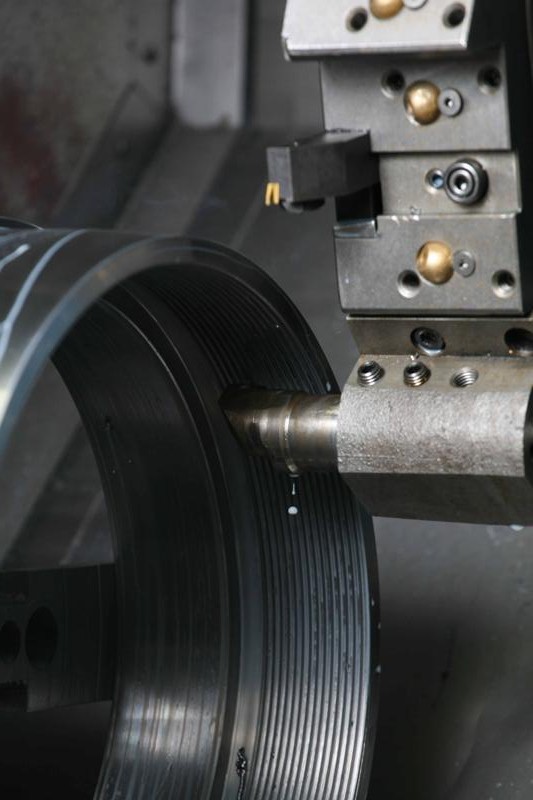

The fundamental difference between the two techniques lies in the movement of the cutting tool. In CNC milling, the cutting tool moves in a fixed pattern, cutting away at the material as it goes. In contrast, CNC turning is primarily used to cut cylindrical shapes in which the cutting tool rotates around the material as it works.

Related Post: What Industries Benefit From CNC Machining?

The Benefits of CNC Milling and CNC Turning For the Manufacturing Industry

In today’s fast-paced manufacturing industry, efficiency is key. CNC milling and turning have become vital tools in improving production processes. These processes offer several advantages, from increased productivity to the accuracy and precision of parts.

CNC milling and turning machines use computer software to manage and carry out tasks with minimal human intervention, allowing manufacturers to produce large quantities of parts quickly and accurately. Additionally, the software also minimizes waste and enables manufacturers to create complex and intricate designs that would be time-consuming to do manually while ensuring consistent quality. Thus, CNC milling and turning have simplified the manufacturing process, allowing businesses to remain competitive in an increasingly global marketplace.

Related Post: CNC Lathe Parts and Terminology

The Cost-Effectiveness of CNC Milling and CNC Turning

When it comes to manufacturing, cost-effectiveness is always top of mind. That’s why CNC machining has been a game-changer. CNC milling and turning are two of the most commonly used methods in CNC machining. Both offer precise, high-quality results, but which one is more cost-effective?

Well, it depends on the project. Factors like the size and complexity of the part, as well as the materials used, can all impact the cost. However, in general, CNC milling is considered to be more cost-effective for complex parts with intricate geometries, while CNC turning is better suited for parts that are less complex and require tighter tolerances.

Experienced Machine Shop in Ohio

D&E Machine Co. provides precision CNC turning services, as well as CNC milling services in Ohio. Read one of our many success stories on our website where we exceeded our customer’s needs, including our patented ice ball press.

We’re based just outside Cincinnati, so if you need machining services in Ohio, Kentucky, or Indiana, request a quote from us today.